Rust Grip ®

- Home Page

- Rust Grip ®

DESCRIPTION

Rust Grip® is a tough, one-part, moisture-cure polyurethane coating that absorbs atmospheric moisture to cure. Rust Grip® is loaded with a metallic pigment for strength and is also resistant to chemical solvents and acid splash. Upon curing, Rust Grip® provides a protective coating film of superior adhesion and flexibility, and is resistant to abrasion and impact.

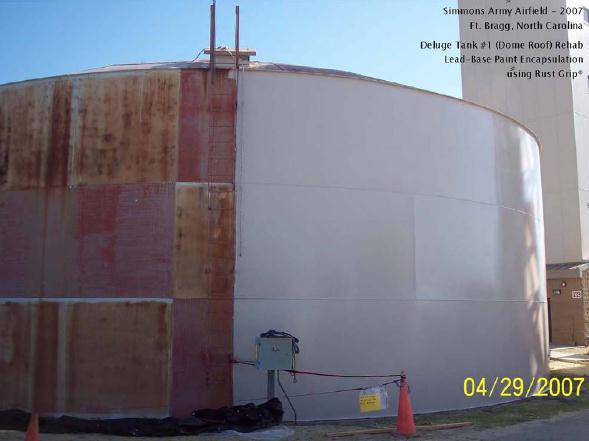

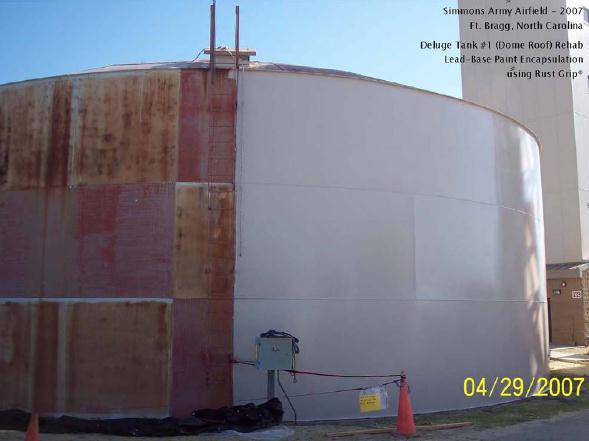

Rust Grip® can be used as a primer or as a one-coating system. It is patented to encapsulate lead-based paints and other toxic materials, including asbestos. Rust Grip® can be applied over pressure-washed, completely dry flash rust and firmly bonded commercial paints. In most cases, a white or near-white blasting is not required. A light to medium surface rust is preferred as the profile.

FEATURES

- Single Component – No mixing part A & B; no pot life, no catalyzation

- One-Coat System

- Fast Cure – humidity accelerates curing – ie over 40% humidity 3 coats in a day – micro climate is the key

- Surface Tolerant – Unique for a Polyurethane Rust Grip® on any surface. Minimal surface preparation. Excellent for minimally prepared surfaces, ie. no sandblasting is needed many times

- Embeds and Encapsules – Not just a surface coating

- Limited Surface Preparation

- Self Priming – “Three coats in one” system

- 1 Product shows up to the job site

- Strength – Non leafing aluminium metallics

- Permeability Rating – 0.24 (below 0.5 is excellent)

- UV Protection

- EPA Approved

- Surface Tensile Strength – 6,780+ psi (478 bar) surface tensile strength. It makes an excellent floor coating

- No More Zinc – Aluminium is a stronger and better long-term investment

- Easy to Apply – Brush, Spray or Roller

- Endures 29,700 rub cycles without exposing existing lead based paint

- Higher Surface Temperature – 60°C (Zinc has maximum temperature at 50°C) – more time for application in the heat

Protects – steel, aluminium, concrete, wood, fibreglass, lead-based paints, and other substrates - Long Shelf Life – 3 years if unopened

- Moisture Barrier – that stops water penetration, prevents corrosion and surface deterioration, and repels dirt, mould, and mildew

- Patented for encapsulating bio-hazardous materials – (asbestos, lead-based paint, and many hazardous materials) and existing rusted surfaces certified (ASTM E1795) Biohazard Encapsulator

- Breaks The Rules – Minimum Surface Preparation = Better Results

- No Hot Permit Required – (60% of the cost reduced in the surface preparation removing clean up, containment, sound as factors)

- Use in Dangerous environments – Use No Spark Hand tools for preparation of Corrosion and High Pressure Water 6000+ psi removes loose corrosion

- Submergible – in 100% nitric acid without any effects. Designed to withstand acids, salts, and caustics with no loss of integrity

- Class A fire coating – In case of fire, Rust Grip® will help to prevent spread of, and will not contribute to the fire

20+ year lifespan – under normal conditions - Passed 15,000 hours (= 30 years) of salt spray testing which far exceeds the marine specifications with a perfect 10 score with no corrosion development (ASTM C117)

CHARACTERISTICS

| Product Chemistry | Polyurethane |

| Volume Solids | 51.4% |

| VOC Level | 380 g/L, 3.17 lbs./gal. |

| Dry Time (at 70˚F) | 30-60 minutes to tack free |

| Hygroscopic | Cures by absorbing moisture in the air |

TYPICAL USES

1.As a coating to encapsulate rust, lead-based paints and other hazardous materials.

2. As a protective coating on metal, concrete, wood, etc. to add strength and prevent deterioration.

3. As a one-coat system on new or existing bridges, oil platforms, roofs, and other commercial/industrial surfaces with minimal surface preparation and non-sparking.

APPLICATION METHODS

Rust Grip® can be applied to concrete or masonry substrates. The coating can be applied by spray, brush or roller. For specific instructions on surface preparation, mixing and application, please refer to the SPI’s application instructions for RUST GRIP® (millage may vary due to surface profile).

Az

Az En

En Ru

Ru